HDI PCB – 8-Layer 1.5mm Thick with TU-883 Material for High-Speed, Low-Loss Applications

1. Basic PCB Specifications

| Parameter | Specification |

|---|---|

| Board Type | 8-layer rigid PCB |

| Material Type | TU-883 (ThunderClad 2) |

| Solder Mask | Blue (both sides) |

| Silkscreen Print | White (top side) |

| Surface Finish | ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) |

| Total Board Thickness | 1.45mm ±10% |

| Board Size | 97.3mm x 67.7mm = 1PCS |

| Minimum Hole Size | 0.25mm |

| Solder Mask Thickness | 10µm |

| Minimum Dielectric Thickness | 100µm |

| Minimum Trace Line Width | 150µm |

| Minimum Spacing | 160µm |

| Blind Vias | Yes, L1-L2, L7-L8 |

| Buried Vias | Yes, L2-L7 |

| Back-Drilled Vias | Yes, L1-L6 |

| Impedance Control | |

| - 100Ω Differential Pairs | Top layer, 4mil/5mil trace/gap, reference layer 2 |

| - 90Ω Differential Pairs | Bottom layer, 4mil/7mil trace/gap, reference layer 7 |

| - 50Ω Differential Pairs | Layer 6, 5mil/6mil trace/gap, reference layers 5 and 7 |

| Counterholes | Applied on the top layer, 90 degrees, 0.5mm deep |

| Edge Plating | Applied on designated areas |

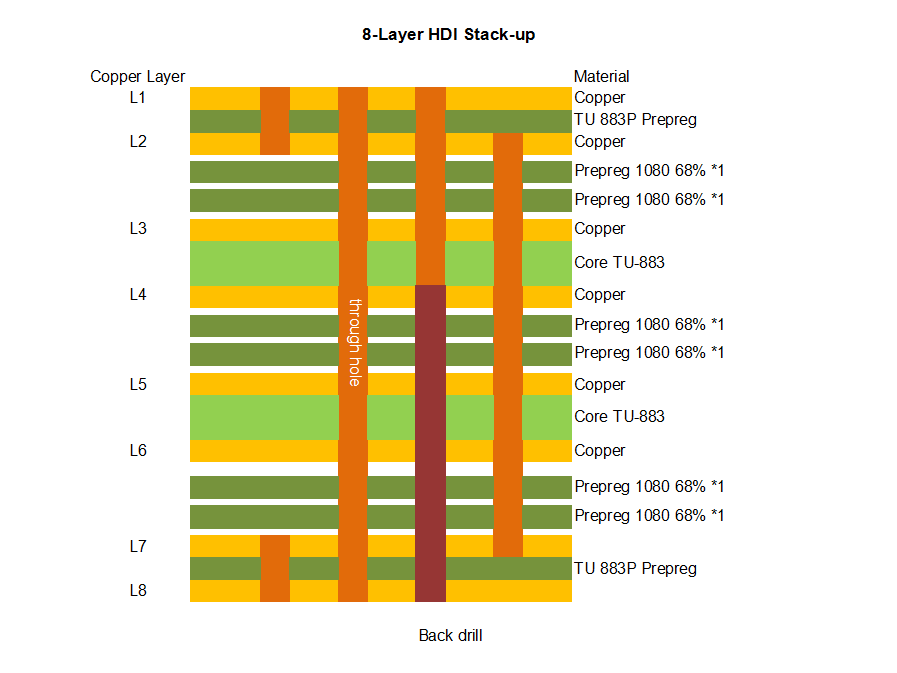

2.PCB Stack-Up: 8-Layer Rigid PCB (Component Side at Top)

| Material | Copper Layer | Thickness (µm) | Specification |

|---|---|---|---|

| Copper | 1 | 45 | 18µm base + 17µm plating |

| TUC-TU883P | Prepreg | 89 | IPC-4101/24 |

| Copper | 2 | 35 | |

| S1000-2MB | Prepreg | 160 | IPC-4101/24 |

| Copper | 3 | 35 | |

| FR-4 TU883 | Core | 254 | IPC-4101/24 |

| Copper | 4 | 35 | |

| S1000-2MB | Prepreg | 160 | IPC-4101/24 |

| Copper | 5 | 35 | |

| FR-4 TU883 | Core | 254 | IPC-4101/24 |

| Copper | 6 | 35 | |

| S1000-2MB | Prepreg | 160 | IPC-4101/24 |

| Copper | 7 | 35 | |

| TUC-TU883P | Prepreg | 89 | IPC-4101/24 |

| Copper | 8 | 35 | 18µm base + 17µm plating |

3.PCB Statistics:

Components: 49

Total Pads: 98

Thru-Hole Pads: 46

Top SMT Pads: 38

Bottom SMT Pads: 14

Vias: 63

Nets: 6

4.Additional Details

Type of Artwork Supplied: Gerber RS-274-X

Quality Standard: IPC-Class-2

Availability: Worldwide

5.Introduction of TU-883 (ThunderClad 2)

TU-883 (ThunderClad 2) is a high-performance, low-loss material designed for high-speed, radio frequency, and wireless applications. Reinforced with woven E-glass, it features a low dielectric constant (Dk) and dissipation factor (Df), making it ideal for environmentally friendly lead-free processes. TU-883 is compatible with FR-4 processes and offers excellent moisture resistance, improved CTE, superior chemical resistance, thermal stability, and anti-CAF capability.

6.Key Features of TU-883

High Tg (TMA): 170°C

Dielectric Constant (Dk): 3.39 @ 10 GHz

Dissipation Factor (Df): 0.0045 @ 10 GHz

Stable Dk/Df Performance: Consistent across frequency and temperature

Compatibility: Modified FR-4 processes

Moisture Resistance: Excellent performance in humid environments

Lead-Free Reflow Process: Fully compatible

Improved Z-Axis Thermal Expansion: Enhanced reliability

Anti-CAF Capability: Prevents conductive anodic filament formation

Through-Hole and Soldering Reliability: Excellent performance

Halogen-Free: Meets environmental standards

7.Typical Applications

Radio Frequency (RF) Systems

Backplanes and High-Performance Computing

Line Cards and Storage Systems

Servers, Telecom, and Base Stations

Office Routers

8.Upgrade Your High-Speed PCB Designs with TU-883!

Whether you're working on RF systems, telecom infrastructure, or high-performance computing, TU-883 HDI PCBs offer the perfect combination of performance, reliability, and cost efficiency. With low dielectric loss, impedance-controlled design, and excellent thermal stability, TU-883 is the ideal choice for your next high-speed PCB project.